15 Sep,2025

Top 5 Double Block And Bleed Valve Manufacturers in the Middle East

As a leading global double block and bleed valve manufacturer, PANS VALVE has been monitoring the growth of the Middle East market. Based on our industry knowledge and global partnerships, we’ve compiled a list of the top 5 DBB valve manufacturers and suppliers in the Middle East that EPC contractors and distributors should know. Double […]

15 Aug,2025

Plug Valve Torque and Operation: Optimizing Performance and Extending Lifespan

Plug valve grease may not be the most glamorous part of valve maintenance, but it plays a critical role in keeping your valves operating smoothly, minimizing torque, and preventing premature failure. When applied and monitored properly, plug valve grease—along with the right actuator selection—can significantly extend the life of your system and reduce maintenance headaches. […]

15 Aug,2025

Plug Valves in the Chemical Industry: Handling Corrosive Media and Ensuring Safety

Plug valves have become a go-to solution for the chemical industry due to their tight shut-off, resistance to corrosive media, and easy maintenance—all critical for handling hazardous fluids safely. In chemical processing plants where leaks could mean serious safety risks or environmental violations, selecting the right valve isn’t just a technical decision—it’s a safety imperative. […]

15 Aug,2025

Understanding Plug Valve Classes: Decoding 1500, 800, and 2500 for Your Application

Selecting the appropriate plug valve class is essential for maintaining operational safety, system reliability, and performance under high-pressure conditions. Whether you’re handling steam, gas, oil, or chemical media, understanding what plug valve class 1500, plug valve class 800, or plug valve class 2500 actually means can help you make informed design and procurement decisions. These […]

15 Aug,2025

3 Way Plug Valve: A Multi-Path Fluid Control Solution

When your fluid control system needs to do more than just open or close, a 3-way plug valve offers a compact and efficient solution. Designed to divert, mix, or isolate flows across multiple lines, these valves simplify system design while delivering precise control. Whether you’re rerouting chemical streams, managing bypass lines, or balancing fluid mixes, […]

08 Aug,2025

Flanged Plug Valve: Connections, Installation, and Application Advantages

A flanged plug valve offers a secure, easy-to-install solution for demanding piping systems where tight sealing and robust connections are essential. From chemical plants to refineries, these valves provide long-term performance, especially in applications where maintenance access and leak prevention are critical. In this article, we’ll walk you through what a flanged plug valve is, […]

08 Aug,2025

Procuring Plug Valves: Inventory Management Strategies for Distributors and Agents

Managing valve inventory management in the valve industry isn’t just about keeping shelves stocked—it’s about predicting demand, streamlining the supply chain, and responding quickly to project-based spikes. Whether you’re a regional distributor or a global procurement agent, the challenges of valve inventory management can be overwhelming without clear strategies. Working closely with a reliable wholesale […]

06 Aug,2025

Essential Maintenance and Troubleshooting Guide for Plug Valves

When industrial flow systems fail, faulty valves are often the hidden culprit—and plug valve troubleshooting is the fastest route to getting back on track. Whether it’s a sticking valve or sudden leakage, timely diagnostics and routine maintenance can prevent unexpected shutdowns and prolong the life of your plug valves. In this guide, we’ll walk you […]

22 Jul,2025

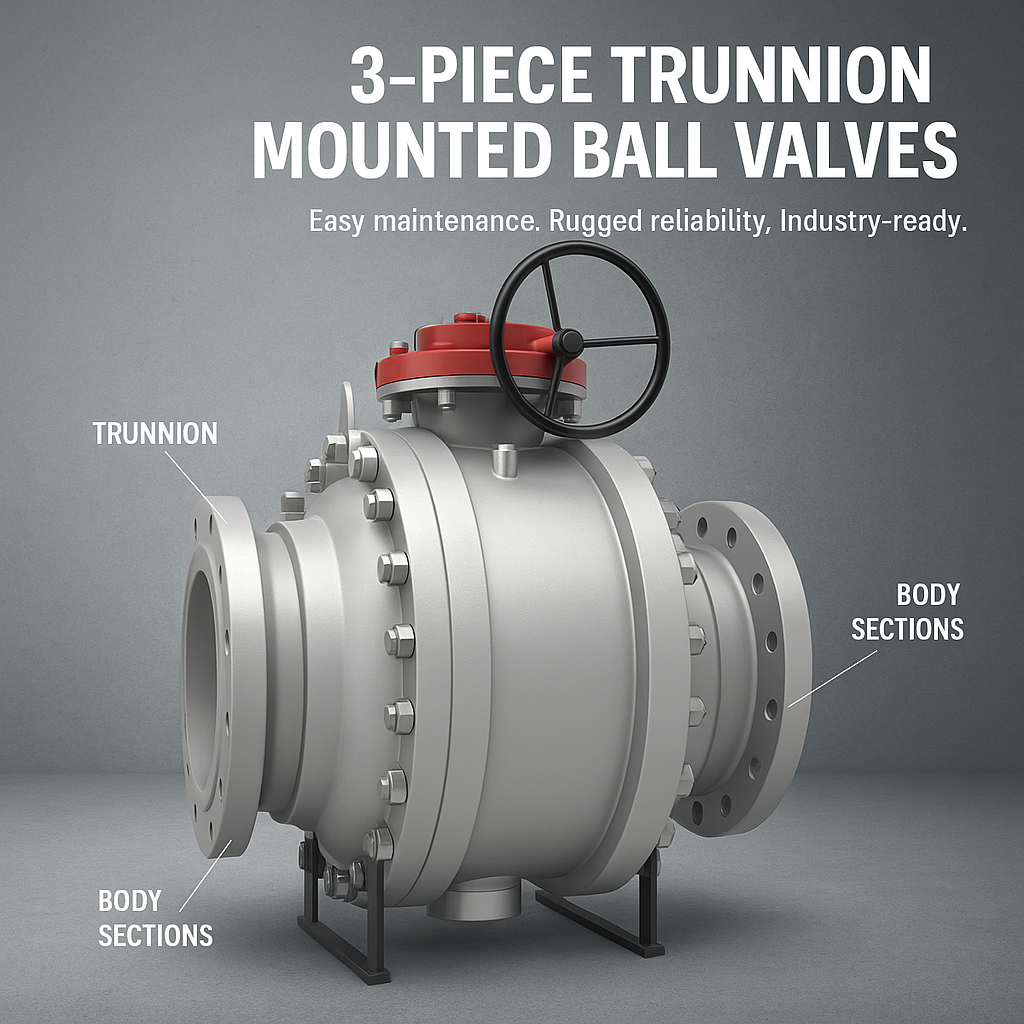

The Advantages of 3-Piece Trunnion Mounted Ball Valves

Some of the benefits of using a 3 piece trunnion mounted ball valve include reduced downtime, easy maintenance, and long-term reliability. These types of valves are ideal for high-pressure systems and media that demand reliable shutoff and regular servicing. Understanding the 3-Piece Body Construction A 3 piece trunnion mounted ball valve is built in three […]

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Butterfly Valve

- Full Metal-Seated Bi-Directional Butterfly Valve

- High Performance Butterfly Valve

- Three-Eccentric Metal Hard Seal Butterfly Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer