26 Jun,2025

Selecting Forged Valves for High-Pressure Applications

Choosing forged valves for high-pressure applications requires considering pressure ratings that exceed operating conditions, material compatibility with process fluids, and temperature resistance for your specific environment. You also need to evaluate flow characteristics, safety margins, end connection requirements, and compliance with industry standards. Additional factors include high pressure valve for water systems, specialized designs for […]

26 Jun,2025

Advantages of Using Forged Steel Valves in Power Plants

Some of the advantages of using forged steel valve construction in power plants include exceptional durability, superior temperature resistance, and leak-proof operation under extreme pressures. These power plant valves also have lower long-term operational costs and deliver reliable performance that maintains safety standards. Why Power Plants Require Superior Valve Performance Power generation facilities operate under […]

25 Mar,2025

The Manufacturing Process of Forged Valves

What Is the Forged Valve Manufacturing Process? A forged valve is made by heating metal and shaping it under high pressure, creating a dense, durable part with excellent mechanical strength. The forged valve manufacturing process is widely used in industries that demand high performance, such as oil and gas, power generation, and chemical processing. In […]

25 Mar,2025

Top 10 Forged Valve Manufacturers in China (2025 Guide)

Looking for the top forged gate valve manufacturers in China? You’re in the right place. China’s industrial valve sector is a global force, especially in forged steel valve manufacturing, offering high-quality products at competitive prices. This guide highlights China’s top 10 forged valve manufacturers and explains everything you need to know—even if you’re new to […]

25 Mar,2025

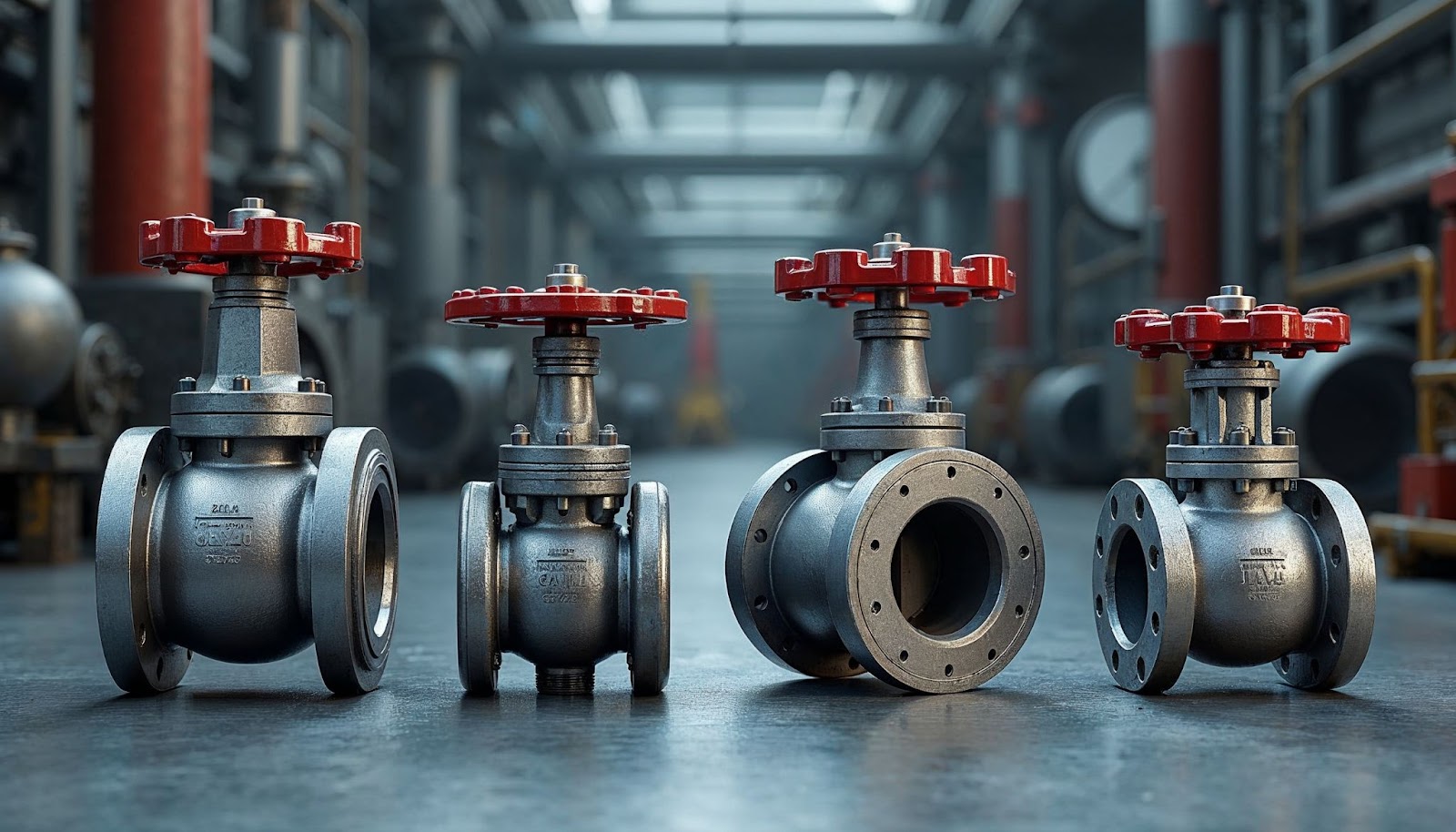

Which Is Better: Cast Steel Valve or Forged Steel Valve?

When comparing forged vs cast valves, forged steel valves typically offer greater strength, reliability, and durability under extreme pressure and temperature. On the other hand, cast steel valves are ideal for complex shapes and cost-sensitive applications. Choosing between them depends on your project’s performance needs and design requirements. This article breaks down the key differences […]

18 Mar,2025

What Are The Different Types of Forged Valves?

Forged valves are critical components used in high-pressure and high-temperature fluid systems. Unlike cast valves, forged valves are created by compressing metal into shape under extreme pressure. This method results in superior strength, durability, and leak resistance—making them the go-to choice for demanding industrial environments. Whether you’re working in oil and gas, chemical processing, or […]

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer