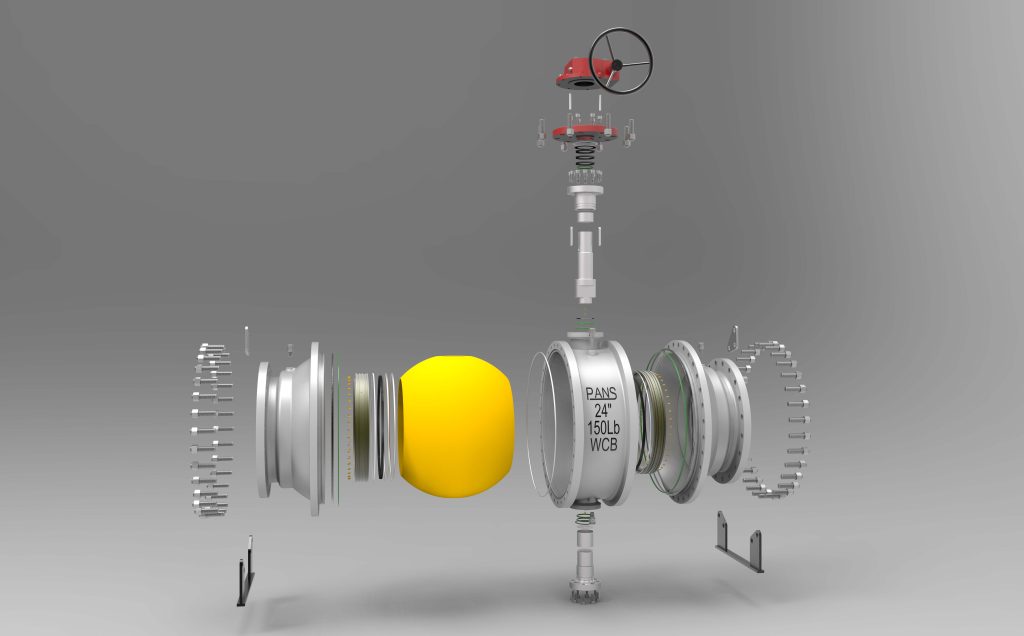

Trunnion Ball Valve

1. Design and manufacture stadnard: API608/API 6D

2. Face to face: ASME B16.10

3. Flange ends standard: ASME B16.5

4. Inspection and test standard: API598

Description

Full port design,BB,Split body,three piece body for 12″ and above,trunnion mounted ball type,blow-out proof stem, fire durable construction, anti-static device, ISO 5211 mounting pad, flanged or BW ends, available with WG operator.

Application

Trunnion ball valves are suitable for use on various kinds of pipelines of Class 150

~ Class2500, PN16 ~ PN160, JIS10K ~ JIS20Kto cut off or turn on the pipeline medium, of which the operation types include worm gear, manual, pneumatic or electric actuators, being in general of flange connection, and butt welding ends connection as well.

Urgent grease injection device

According to customers’ requirement, the trunnion ball valves made by Zhedong company are provided with devices for urgent grease injection, which are on both the stem and seat for the trunnion Ball valves of DN> 150mm (NPS6), and in the body cavity for the valve of DN <125mm. When the O ring of stem or the body seat ring is damage due to accident, the medium leakage between body and stem can be prevented by injecting the sealing grease through the device.

Double-block and bleed functions

In general, Zhedong trunnion ball valve features the front ball sealing design structure. Each seat of the ball valve can separately cut off the medium at both inlet and outlet of the valve to realize double- block functions. When the ball valve is closed, body cavity and two of the body ends can be blocked with each other even if both the inlet and outlet are under pressure, when the medium left in the body cavity might be bled through the relief valve.

Blow-out proof stem

Blow-out proof structure is provided with for the stem, which is positioned by the up-end cap and screw, being guaranteed not to be blown -out by the medium even if at abnormal risen pressure in the cavity.

The Bi-sealing design structure.i.e. seat sealing in front Of the ball and seat sealing behind the ball

According to some special working conditions and customers’ requirement, Zhedong has provided the trunnion ball valve with the Bi-sealing design structure, i.e. seat sealing in front of the ball and seat sealing behind the ball, thus the reliable sealing of the valve is ensured because the valve can perform normally even if one of the effective sealing designs becomes lost due to the abnormal condition.

Regarding the seat in front of the ball, the piston effect formed by the area difference between D1 and D2, plus the pre tightened force of a spring would cause the seat in front of the ball by the pressure difference of the medium before and after the valve to touch the ball closely to form the tightness, of which the sealing force will become bigger as the pressure difference gets higher.

Regarding the seat after the ball, the piston effect formed by the area difference between D2 and D3, plus the pre tightened force of a spring would cause the seat behind the ball to touch the ball closely to form the tightness, of which the sealing force will become bigger as the pressure difference gets higher.

Anti-static design

The ball of the trunnion ball valve gets close contact with each other through the trunnion, adjusting cushion, and down end cap, the passage of static electricity thusforms together with the valve, which may lead the static electricity caused by sparks generated by friction between the ball and seat during on and off performance to the ground to prevent the possible risk of fire or explosion.

Self-relief in the bod cavity

As the liquid medium left in the body cavity gasifies due to increased temperature, the pressure in the body cavity becomes abnormally higher, when the medium itself in the cavity would propel the seat and self-relieves the pressure to ensure the safety of valve.

Fire safe design

With the valve heated in a fire application, the nonmetal material parts such as seat sealing ring of PTFE, O ring for the stem, and sealing gasket for body and bonnet, might be damaged due to high temperature. Zhedong’s special design of auxiliary metal to metal or the graphite seal is provided for the trunnion ball valve to effectively prevent both internal and external leakage of the valve. As required by customers, Zhedong’s fire safe design for the trunnion ball valve meets the requirement of API 607, API 6Fa, BS 6755 and JB/T 6899.

Related products

Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

Globe Valve

- Cast Globe Valve

Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

Slurry Valve

- Slurry Valve