Everything You Need to Know About Plug Valves

When it comes to fluid control systems, plug valves hold a critical role as they serve as a primary means of controlling fluid flow in industrial applications.

The plug valve’s design, which includes a rotating plug that blocks or allows fluid passage, is both simple and effective.

Plus, the simplicity of the plug valve’s design, combined with versatility and ease of maintenance, makes it a top choice among different types of valves.

So, read on as this article will give you an in-depth understanding of plug valves, their functionality, and the various types available.

Plug Valves as Essential Components in Fluid Control Systems

Plug valves are crucial in fluid control due to their straightforward design, which relies on a cylindrical or conical plug to regulate flow.

They offer a high degree of reliability, especially in applications that require frequent switching between open and closed positions.

With just a few components, plug valves can be quickly and easily serviced, adding to their popularity in industrial applications.

In addition to their reliable on/off control, plug valves are particularly suitable for high-pressure, high-temperature environments.

Unlike other valve types, they can effectively manage various fluids, from gases to slurries.

Plug valves are designed to minimize leakage, which is vital in hazardous applications where fluid containment is crucial.

What’s the Purpose of a Plug Valve?

The primary purpose of a plug valve is to regulate the flow of liquids or gases within a system.

By controlling the flow, plug valves prevent leaks, maintain system pressure, and enable safe system operations.

Their design allows for quick, effective opening and closing, making them suitable for applications that require frequent operation.

Plug valves excel in applications where flow needs to be reliably stopped or redirected, such as in pipeline systems for oil and gas, or in water treatment facilities where certain chemicals or treatments are introduced selectively.

Plug valve manufacturers design these valves with durability in mind, often creating them from materials resistant to corrosion and wear to ensure a longer lifespan in challenging environments.

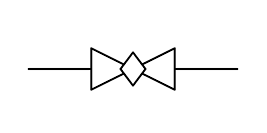

What is the Plug Valve Symbol?

In engineering schematics, the plug valve symbol is a visual shorthand that helps technicians identify and understand the valve’s role within a system.

Credits to www.cpvmfg.com

Typically, the plug valve symbol consists of a diamond shape, with a line representing the open passageway.

This visual indicates that fluid can flow freely through the valve in an open position.

If the diamond is crossed by a line or otherwise closed, it indicates the valve is in a closed position.

The use of standard symbols in engineering ensures consistent understanding and communication, reducing the risk of operational errors.

Whether on a manufacturing floor or in a control room, understanding the plug valve symbol aids technicians in quickly identifying the valve’s function and status, which is vital for efficient system operation.

How Does a Plug Valve Work?

A plug valve operates on a relatively simple mechanism that is highly effective for fluid control.

Here’s a step-by-step look at how plug valves work:

Step 1: Positioning of the Plug

Inside the valve body is a plug with a cylindrical or conical shape. This plug contains a hole that acts as a channel through which fluids can pass.

When the plug is positioned with the hole aligned with the pipeline, the valve is open, allowing fluid to flow.

Step 2: Rotation of the Plug

The plug rotates within the valve body to either align with or block the pipeline.

A 90-degree turn typically shifts the valve between fully open and fully closed, making plug valves easy to operate and adjust.

Step 3: Sealing Mechanism

Plug valves are designed to create a tight seal when closed, preventing leakage.

In some models, the plug and the valve body contain special seating materials to enhance sealing, ensuring that no fluid escapes.

Step 4: Control of Fluid Flow

With adjustable rotation, plug valves allow operators to precisely control the flow of liquids or gases.

This control is especially useful in applications where varying flow rates are necessary.

Some plug valves feature a “quarter-turn” design, enabling quick transitions between open and closed positions.

How Do You Tell if a Plug Valve is Open or Closed?

To identify whether a plug valve is open or closed, the handle orientation is usually the best indicator.

In plug valves with a handle, when it aligns with the flow direction, the valve is open, allowing unrestricted fluid movement.

When the handle is perpendicular to the flow direction, the valve is closed, blocking fluid movement.

For maintenance and operation safety, knowing a valve’s status at a glance is essential.

This feature is particularly useful in emergency scenarios, as operators can quickly assess valve positions and take necessary actions to manage the system effectively.

When to Use a Plug Valve?

Plug valves are particularly suited for applications requiring a reliable and easy-to-operate on/off mechanism.

These valves are used in industries such as oil and gas, chemical processing, water treatment, and more.

Their ability to handle high-pressure environments and their minimal maintenance requirements make them a preferred choice for systems that require quick and frequent flow control adjustments.

What’s the Difference Between a Plug Valve and a Needle Valve?

The main difference between a plug valve and a needle valve lies in their design and applications.

While plug valves use a plug mechanism for on/off control, needle valves have a pointed, tapered stem for more precise flow regulation.

Needle valves are used when finer flow adjustments are needed, like in laboratory setups or specific fluid metering applications.

What’s the Difference Between a Plug Valve and a Butterfly Valve?

Butterfly valves and plug valves both control fluid flow, but they differ in construction and typical applications.

Butterfly valves use a rotating disc and are ideal for larger-diameter pipes, whereas plug valves rely on a rotating plug and are generally better for high-pressure systems.

Butterfly valves are lighter and often more cost-effective, making them suitable for larger, lower-pressure systems, while plug valves are more durable for high-pressure applications.

What’s the Difference Between a Ball Valve and a Plug Valve?

Ball valves contain a spherical ball with a hole through it, while plug valves use a cylindrical or conical plug.

Ball valves are often preferred for applications requiring tight shutoff with less frequent maintenance, while plug valves excel in durability and simplicity, making them easier to maintain and repair in high-use applications.

In a nutshell, the difference between plug valves and ball valves primarily lies in their structure.

Is a Plug Valve the Same as a Gate Valve?

Though both can stop fluid flow, plug valves and gate valves have distinct designs.

Gate valves utilize a sliding gate that moves up and down, making them better suited for applications that require a slower or gradual closure.

In contrast, plug valves are faster to open and close, providing a better option for quick-response applications.

What Different Types of Plug Valves Are Offered by Pans Valve?

Pans Valve offers several types of plug valves, each with unique features to cater to different applications.

Sleeve Plug Valve

Main Structural Features: The sleeve plug valve is known for its bolt cover, which allows the plug to rotate 90 degrees.

Its sealing is achieved via a surface around the sleeve with a unique 360-degree metal edge that provides self-cleaning.

Benefits: The valve design minimizes media accumulation, which is ideal for handling sticky substances.

Its metal edge enhances durability, making it well-suited for operations with demanding flow conditions.

Orbit Plug Valve

Main Structural Features: The orbit plug valve features sealing rings around the valve disc and includes a bolt bonnet OS & Y lifting-round plug mechanism.

Principle of Operation: Opening the valve aligns the plug’s channel with the valve body for minimal pressure loss.

Rotating the hand wheel causes the plug to close the valve gradually. This design allows the valve to handle high-pressure applications smoothly.

Inverted Pressure Balance Lubricated Plug Valve

Main Structural Features: The inverted pressure balance lubricated plug valve is equipped with a bolt cover and a flip-chip pressure balance system.

An oil groove between the valve body and the sealing surface enhances sealing.

Benefits: The added lubrication makes it well-suited for high-pressure and high-temperature applications, increasing the valve’s longevity and leak-prevention capabilities.

For more plug valve variations and customization, contact Pans Valve now!

Plug Valves: In A Nutshell

Plug valves offer reliable and efficient on/off control and are essential in industries where safety and fluid control are priorities.

The types of plug valves provided by manufacturers like Pans Valve — such as the sleeve plug valve, orbit plug valve, and inverted pressure balance lubricated plug valve—demonstrate the adaptability of plug valves for various uses.

Understanding the difference between plug valves and other valve types helps engineers select the best fit for their systems, ensuring optimal performance in high-pressure, high-temperature environments.

Resources

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer