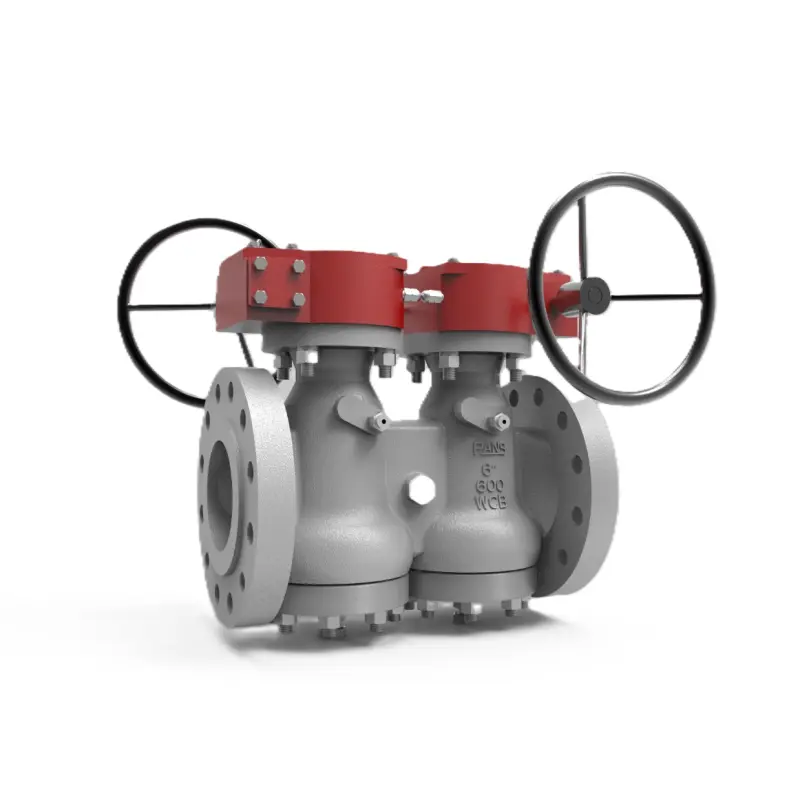

Twin Seal Double Block And Bleed Valves: The Ultimate In Positive Isolation

A twin seal double block and bleed valve delivers zero-leakage isolation for pipelines, storage, and hazardous process systems. It’s why DBB valve manufacturers and suppliers highlight twin seal technology as the gold standard in safety and efficiency.

How Twin Seal DBB Valves Work

Unlike traditional setups that use two separate valves and a bleed, a twin seal DBB valve integrates both block valves and the bleed port into one compact body. This design is widely promoted by leading DBB valve manufacturers because it reduces leak paths and simplifies maintenance.

- Closing: The plug rotates, then lowers, forcing sealing slips outward against the body.

- Sealing: The slips compress seals to form upstream and downstream barriers.

- Bleeding: The bleed port confirms integrity; if no pressure escapes, isolation is proven.

- Opening: Slips retract before rotation, preventing abrasion and extending life.

PANS emphasizes this design because it offers reliability even at low or vacuum pressures, where other valves that depend on line pressure may fail. This is why PANS has earned trust as a twin seal double block and bleed valve manufacturer serving critical industries worldwide.

Why They Are Used

A twin seal double block and bleed valve supplier usually stresses one main point: assurance. These valves give operators confidence that the line is fully sealed, which matters when dealing with hazardous or expensive fluids. They also cut down on downtime because maintenance teams can work on a section without shutting down the whole system. In multi-product lines, where even a small leak could ruin an entire batch, they ensure safety by keeping fuels and chemicals from mixing.

If you want to compare how other valve types compare, see our guide on single-block vs. double-block and bleed valves.

Top Twin Seal DBB Valve

As a premier Twin Seal DBB Valve manufacturer, we provide API-certified valves for critical zero-leakage isolation. Ensure operational safety.

View More Details

Key Advantages of Twin Seal Technology

A double block and bleed twin seal valve offers unique performance features:

- Zero leakage: The mechanical wedge action guarantees bubble-tight seals independent of line pressure.

- Reduced wear: Retracting slips prevent rubbing during rotation, extending seal and body life.

- Compactness: One integrated valve replaces multiple units, reducing installation weight and leak paths.

- In-line serviceability: Some models allow slip replacement without removing the valve.

These features make twin seal designs especially attractive to DBB valve manufacturers and end-users seeking long-term reliability.

Applications in Critical Industries

A twin seal double block and bleed valve supplier focuses on industries where leakage is unacceptable. Metering stations use these valves to protect accuracy, since even the smallest leak past a closed seat can throw off measurement results.

In multi-product manifolds, twin seal valves maintain complete separation between fuels and chemicals. This prevents costly contamination and protects product integrity in pipelines and storage systems.

They are equally important in aviation fueling and pipeline isolation. Hydrant lines at airports require quick, verifiable shutoff during pressure tests, and maintenance crews depend on proven isolation before entering a line. For DBB valve manufacturers, these are the core applications that define the value of twin seal technology.

PANS VALVE: Delivering Ultimate Safety

As a twin seal double block and bleed valve manufacturer, PANS has built a reputation on “zero leakage” and “high safety.” Our strict CNC-driven production and ISO/API-certified processes position us alongside the top DBB valve manufacturers globally.

With 24-hour quotations and 20-day delivery, PANS stands out among any double block and bleed valve supplier network. We back that speed with robust testing that ensures every twin seal product performs in high-risk applications.Our record is unmatched: 100% customer satisfaction, no negative reviews, and verifiable safety in oil, gas, and chemical processing. For EPC contractors tracking upcoming opportunities, explore our insights on 2024–2026 top valve exhibitions.

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Butterfly Valve

- Full Metal-Seated Bi-Directional Butterfly Valve

- High Performance Butterfly Valve

- Three-Eccentric Metal Hard Seal Butterfly Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer