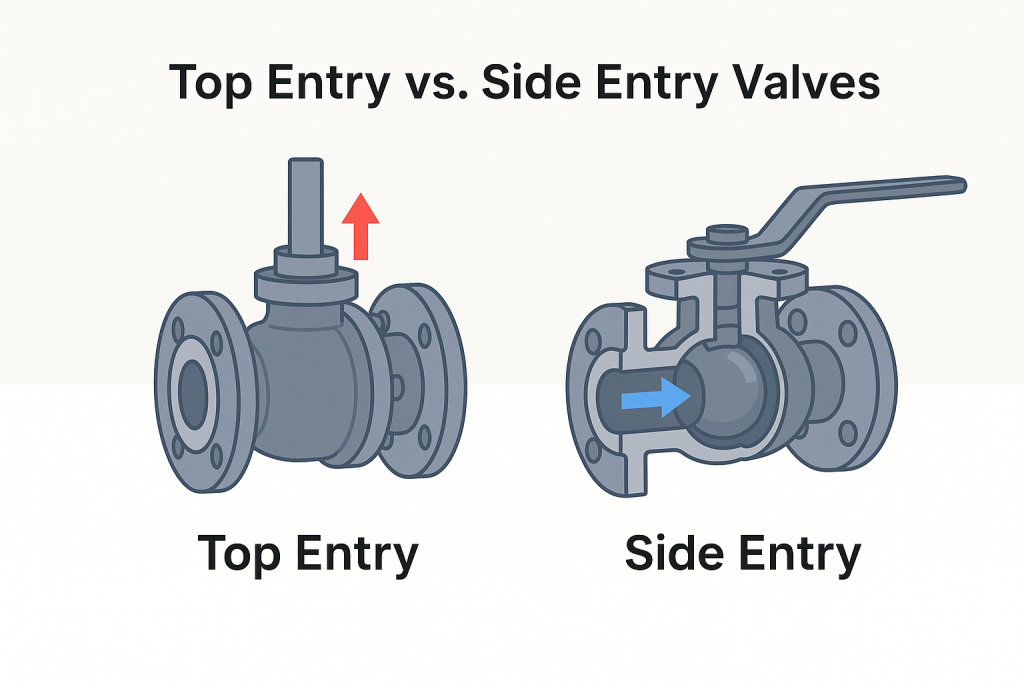

Top Entry vs. Side Entry Trunnion Ball Valves: What Project Managers Need to Know

If your project demands frequent in-line maintenance, limited space for valve removal, or fast part replacement, a top entry trunnion ball valve is the better fit. If you’re prioritizing lower cost and standard maintenance methods, a side entry trunnion ball valve may work better.

The Side Entry Trunnion Ball Valve (2-Piece/3-Piece Construction)

Side entry trunnion ball valves are assembled from two or three pieces and loaded from the side, with the ball inserted during manufacturing. This design is widely used due to its ease of assembly and cost-effective construction.

Pros of Side Entry Trunnion Ball Valves

- Easy to Produce: Side entry trunnion ball valves are simpler to manufacture and often more affordable. They work well for standard above-ground installations and systems with clean media.

- Lower Upfront Cost: For large-scale installations or cost-conscious projects, side entry valves offer financial advantages without sacrificing basic performance.

- Familiar in the Field: Their widespread use means easier sourcing, quicker training, and smoother integration in most standard systems.

Cons of Side Entry Trunnion Ball Valves

- Maintenance Requires Removal: Internal access needs full valve disassembly, making it harder to maintain during operation or in-line.

- Not Ideal for Buried Lines: In welded or buried lines, removing the valve can be time-consuming and expensive.

- Limited Seat Options: Typically uses soft seats, which are not suited for extreme heat, pressure, or particle-filled fluids.

Your Direct Top Entry Trunnion Ball Valve Factory

Source directly from a leading top entry trunnion ball valve factory for valves that allow for fast, inline maintenance and repair. Our API 6D certified valves are engineered for maximum reliability in high-pressure applications, ensuring superior performance.

View Specifications

The Top Entry Trunnion Ball Valve

Pros of Top Entry Trunnion Ball Valves

- Easy In-line Access: Top entry valves allow technicians to service internals without removing the valve from the line. That makes repairs faster and safer.

- Suitable for Harsh Environments: Often paired with metal seats, they’re ideal for high-temp, high-pressure, or corrosive media. They’re commonly used in offshore, buried, or high-spec pipelines.

- Long-Term Reliability: Fewer disconnections and better sealing under stress help extend operational life and reduce overall cost of ownership.

Cons of Top Entry Trunnion Ball Valves

- Higher Initial Cost: Due to design complexity, top entry valves usually cost more upfront.

- Requires Vertical Clearance: You’ll need space above the valve for servicing, which may not suit tight installations.

- Longer Lead Times: Custom builds or international sourcing may result in slightly longer delivery schedules depending on project size.

Materials and Valve Seat Options

The right valve seat depends on your application. PANS offers both soft and metal seats options based on your process demands:

- Soft seats: Best for standard liquids and gases, with lower temperature and pressure.

- Metal seats: Ideal for high-pressure steam, abrasive slurries, or corrosive chemicals.

- High-temp applications: Our metal-seated top entry valves handle service above 400°C.

Need a material recommendation? We’ll help you match the valve to your media and system pressure.

Decision Matrix: Which Design is Better for Your Service?

If your system requires fast in-line servicing with minimal downtime, especially for buried or welded pipelines, a top entry trunnion ball valve is typically the better fit.

In contrast, side entry trunnion ball valves are more cost-efficient upfront and are a solid choice when your setup allows for full valve removal and maintenance off the line.

Here’s a quick breakdown to help you compare both options based on your service requirements:

| Factor | Side Entry Trunnion Ball Valve | Top Entry Trunnion Ball Valve |

| Maintenance Access | Needs full removal | In-line maintenance |

| Initial Cost | Lower | Higher |

| Repair Time | Longer due to disassembly | Shorter and safer |

| Suitability for Welded Lines | Less practical | Well-suited |

| Ideal Media Types | General use | High-temp, abrasive, or corrosive fluids |

| Valve Seat Compatibility | Soft seat for general duty | Metal seat for high-spec applications |

When Design Impacts Safety and Inspection Cycles

Beyond cost and convenience, valve entry design can influence system safety and inspection scheduling.

Top entry valves allow for periodic checks without disrupting pipeline connections, which supports compliance in regulated environments.

In contrast, side entry valves may require more planning during shutdowns since complete removal is often necessary.

If your facility has strict inspection cycles or limited windows for intervention, entry type should be part of your risk assessment and service planning.

Conclusion

If you’re working with welded pipelines, buried valves, or any system where downtime is expensive, the top entry trunnion mounted ball valve offers better serviceability and long-term reliability. For less complex systems with easier access and lower pressures, a side entry trunnion ball valve offers cost savings.

PANS supports both options. As one of the leading top entry trunnion mounted ball valve manufacturers, we offer tailored solutions and guidance. Whether you’re sourcing for heavy oil installations in Venezuela or chemical plants in Turkey, our engineers will help you choose the right configuration.

Need pricing or specs fast? Our team delivers quotes and drawings within 24 hours. That way, you can move from spec to site without delay

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Butterfly Valve

- Full Metal-Seated Bi-Directional Butterfly Valve

- High Performance Butterfly Valve

- Three-Eccentric Metal Hard Seal Butterfly Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer