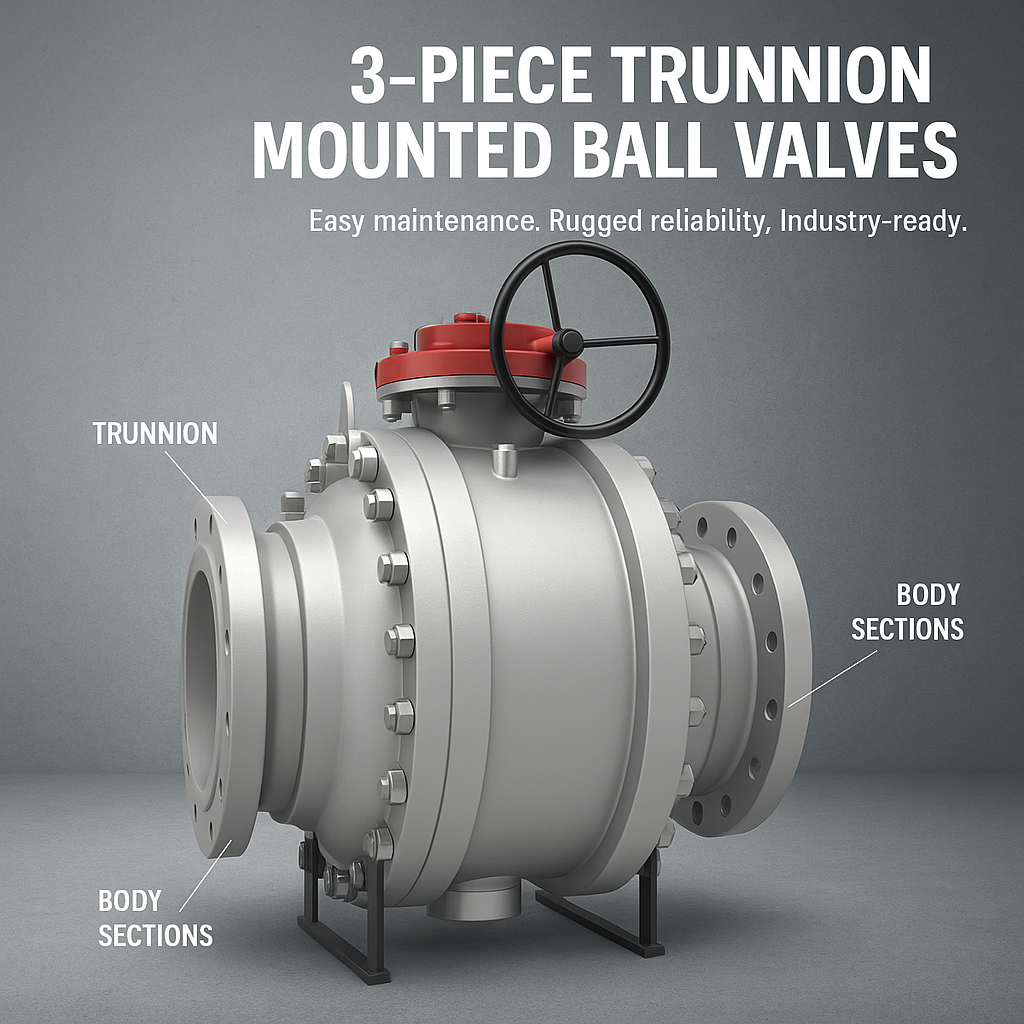

The Advantages of 3-Piece Trunnion Mounted Ball Valves

Some of the benefits of using a 3 piece trunnion mounted ball valve include reduced downtime, easy maintenance, and long-term reliability. These types of valves are ideal for high-pressure systems and media that demand reliable shutoff and regular servicing.

Understanding the 3-Piece Body Construction

A 3 piece trunnion mounted ball valve is built in three main parts:

- Two end caps: These connect to the pipeline and stay in place during maintenance.

- Center body: Houses the ball, seats, and stem. This section can be removed without disturbing the pipeline.

- Bolted connections: Allow for fast disassembly when repairs are needed.

This structure allows for direct access to internal components without disconnecting the valve from the line. Compared to fully welded or one-piece designs, it simplifies repair, testing, and part replacement.

The trunnion mounting ensures the ball is anchored. Pressure doesn’t push the ball into the seats, which means less wear and more consistent sealing.

Key Advantage #1: Ease of Maintenance and Repair

In process industries, every minute of downtime costs money. A 3 piece trunnion mounted ball valve keeps those losses low.

How the Center Section Can Be Swung Out

When service is needed, the center body can be swung or removed while the valve remains connected to the pipeline. Technicians can replace seats, seals, or the ball without cutting or re-welding anything.

This means faster turnaround, less labor, and lower long-term costs. It’s especially useful in plants where access is limited or systems run continuously.

Key Advantage #2: Versatility in End Connections

Every pipeline setup is different. The 3 piece design supports multiple end configurations: threaded, flanged, socket weld, or butt weld.

That makes it easier to match the valve to existing infrastructure. If you’re retrofitting old lines or designing for future modularity, a 3pc trunnion ball valve gives you that flexibility.

This modularity is also helpful when switching media types or adapting to new process requirements.

Key Advantage #3: Enhanced Safety and Compliance

Many 3 piece trunnion mounted ball valves are designed to meet strict safety standards like API 6D and ISO 14313.

Options such as fire-safe seals, anti-static features, and pressure relief functions support safer operations in hazardous environments. This is especially valuable in industries handling flammable, corrosive, or high-pressure media.

Your Direct Top Entry Trunnion Ball Valve Factory

Source directly from a leading top entry trunnion ball valve factory for valves that allow for fast, inline maintenance and repair. Our API 6D certified valves are engineered for maximum reliability in high-pressure applications, ensuring superior performance.

View Specifications

Comparing 3-Piece vs. 2-Piece and Welded Body Designs

| Feature | 3-Piece Trunnion Valve | 2 piece trunnion ball valve | Fully Welded Body Valve |

| Maintenance Access | Easy internal access without pipeline removal | Partial disassembly required | No access after installation |

| End Connection Flexibility | High (supports multiple end types) | Moderate (fewer options) | Fixed (welding only) |

| Suitability for Retrofitting | Excellent for upgrades or modifications | Better for new builds | Not ideal for future modifications |

| Cost Over Lifecycle | Cost-effective through service life | Lower upfront, higher maintenance cost | High initial cost, low maintenance |

| Space Requirements | Moderate | Compact | Most compact |

Typical Applications for 3-Piece Trunnion Valves in Process Industries

PANS designs valves with key industries in mind. Our 3 piece trunnion mounted ball valve is tailored to sectors where uptime, pressure control, and reliable shutoff matter most.

- Oil & gas: The valve is used in upstream and downstream systems where pressures run high and operations can’t afford leaks or valve failure.

- Chemical processing: It supports aggressive or corrosive fluids, with options for special seat materials and fire-safe design.

- Water treatment: The 3-piece design ideal for filtration lines and chemical dosing where the valve may need inspection or cleaning between cycles.

- Metallurgy and Mining: It handles slurry, steam, and abrasive flow media while offering easy repair access in hard-to-reach areas.

These industries rely on 3pc trunnion ball valves for both isolation and control, especially when conditions are too demanding for simpler valve types.

Built for Performance, Backed by PANS

Our 3 piece trunnion mounted ball valves are made to meet global standards such as API 6D and ISO 14313. With options for fire-safe, anti-static, and double block and bleed configurations, each valve is engineered for real-world use.

If you’re comparing with a 2 piece trunnion ball valve, you’ll notice the 3-piece design brings more flexibility and repairability, with only a slight increase in footprint.

We manufacture in compliance with CE, API, and ISO, and support custom specs for end users, EPCs, and OEMs. Our delivery time averages 20 days, even on large orders.

Whether you’re updating a treatment plant or engineering a new refinery, our team can help you choose the right specs and get it on site quickly.

Summary: Why Choose a 3-Piece Trunnion Ball Valve?

If you’re dealing with high pressure, critical shutdown lines, or frequent maintenance cycles, the 3 piece trunnion mounted ball valve gives you the reliability you need with the flexibility to service it anytime.

Compared to a 2 piece trunnion ball valve or fully welded body, it delivers a unique combination of safety, adaptability, and cost control over the valve’s life cycle.

Need help choosing the right configuration? Get in touch with us today. We help industries move with confidence.

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Butterfly Valve

- Full Metal-Seated Bi-Directional Butterfly Valve

- High Performance Butterfly Valve

- Three-Eccentric Metal Hard Seal Butterfly Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer