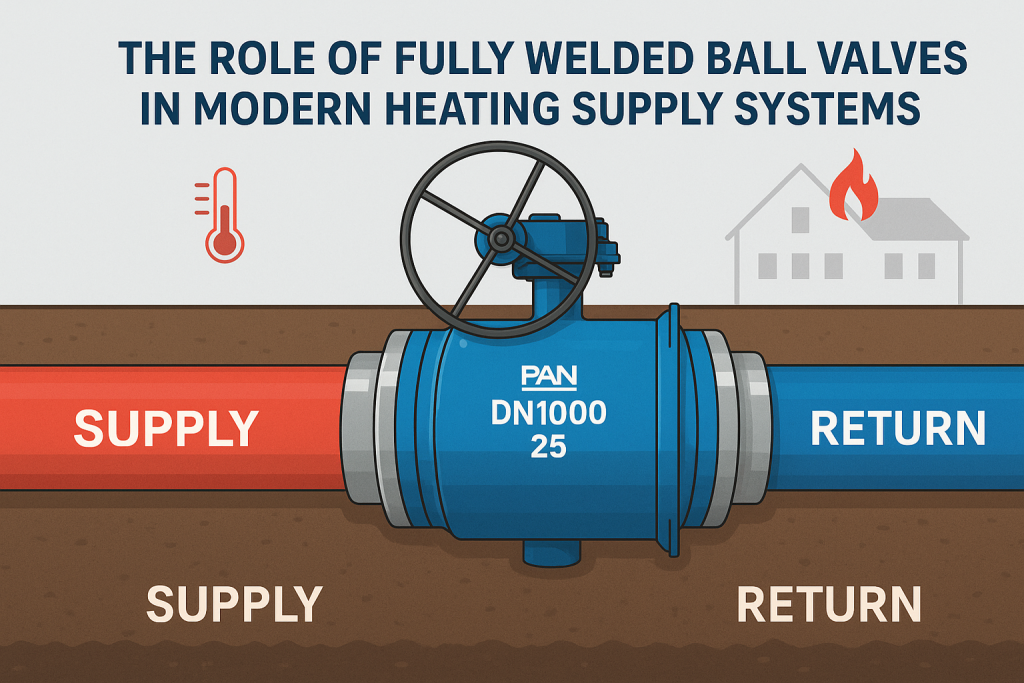

The Role of Fully Welded Ball Valves in Modern Heating Supply Systems

Fully welded ball valves ensure long-term efficiency, safety, and zero leakage in modern heating networks. They handle temperature shifts, resist high pressure, and work reliably for years without maintenance. This makes the heating supply fully welded ball valve a preferred choice for district and industrial networks.

Challenges in Heating Networks: High Temps, Pressure, and Longevity

Heating systems face constant stress. Pressures run high, temperatures fluctuate, and networks often run for decades. These systems can’t afford leaks, failures, or repeated maintenance.

Most pipelines are buried or insulated. That makes access difficult and repairs expensive. Add in seasonal temperature swings and thermal expansion, and it’s easy to see why many standard valves fall short over time.

Urban district heating, in particular, demands reliability. Leaks reduce system efficiency and can damage surrounding infrastructure or disrupt urban services. Once installed, the valve must keep working for decades without adjustment.

Why Fully Welded Ball Valves Are the Ideal Solution

Thermal Expansion

As pipelines heat up and cool down, materials expand and contract. A fully welded body ball valve absorbs that stress without coming apart. Welded connections don’t loosen under heat, and the valve body moves as one with the pipe.

Zero Leakage

Leaking valves lower system efficiency and create safety hazards. Fully welded valves remove external joints and flanges, which are the main leak points in standard valves. The result is a sealed unit that holds tight even in extreme conditions.

In cities, that matters. Zero leakage keeps energy inside the system and protects surrounding infrastructure from heat and water damage.

Maintenance-Free Design

Once buried or insulated, valves are difficult to access. With fully welded valves, there’s nothing to retighten, reseal, or lubricate. That makes them ideal for heating mains, buried branch lines, and industrial heat loops.

They handle both full-bore and reduced-bore setups, adapt to manual or automatic actuation, and support long-term operation without external service.

Your Expert Underground Fully Welded Ball Valve Manufacturer

As a premier underground fully welded ball valve manufacturer, we deliver certified valves engineered for long-term, maintenance-free performance in critical buried applications. Partner with us for reliable solutions that guarantee operational safety and direct-from-factory value.

View Specifications

Technical Features That Matter

Fully welded valves used in heating systems often include a trunnion-mounted ball, spring-loaded seat rings, and fire-safe or anti-static design. These details help maintain sealing pressure under load, prevent electrical buildup in gas pipelines, and ensure operational safety during extreme events.

Soft-seated options suit clean water-based heat transfer. Metallic seats can handle steam or glycol-based fluids at higher temperatures. This adaptability makes them a smart fit for both municipal and industrial use.

Material Selection and Bore Options

Valve body material must match both pressure class and media type. Carbon steel suits most city heat systems. Stainless steel works best in chemically treated circuits or high-temperature industrial environments.

Use full-bore valves when flow consistency is key, like in pump discharge lines. Reduced-bore valves fit better in low-flow branch lines where cost and space are limited.

Quick Comparison: Fully Welded vs Traditional Valves

| Feature | Fully Welded Ball Valve | Traditional (Split-Body) Valve |

| Leakage Risk | No external joints, sealed design | Flanged or bolted joints may loosen over time |

| Maintenance Needs | Maintenance-free after installation | Requires periodic resealing and inspection |

| Installation Type | Suited for buried and insulated pipelines | Better for accessible, above-ground installs |

| Lifespan in Harsh Conditions | 20+ years in pressurized thermal systems | Shorter due to gasket fatigue and bolt stress |

| Pressure/Temp Resistance | Withstands high pressure and thermal expansion | Less resistant to long-term thermal cycling |

| Application Fit | Ideal for district heating and industrial supply | Better for general-purpose or lower-spec systems |

Case Study: Upgrading a Heating Network in Kazakhstan with Our Valves

Feature: PANS supplied a series of heating supply fully welded ball valves to upgrade an aging district heating system in northern Kazakhstan.

Advantage: Each valve came with a fully welded body, zero external leak paths, and a maintenance-free internal design. That meant fewer access points and no service requirements for decades.

Benefit: Customers reported better system efficiency, lower energy loss, and no unplanned shutdowns. Even in Central Asia’s extreme winters, the valves held tight. PANS also delivered the order within 20 days, a key win for contractors working under a strict project timeline.

The project reinforced PANS’s position as a trusted China heating supply fully welded ball valve supplier for international heating infrastructure.

Conclusion: Improving Efficiency and Reliability in Heating Supply

Heating networks need valves that work under pressure, survive the cold, and don’t require regular upkeep. That’s why engineers and contractors turn to fully welded vs traditional valves.

Whether it’s a carbon steel fully welded ball valve for a buried city main, or a stainless steel fully welded ball valve for a high-temperature industrial loop, the design matters.

PANS manufactures each valve at our China manual fully welded ball valves factory, with fast production cycles, precision welding, and zero-compromise testing. All units are built to CE, API, and ISO standards.

From city grids to factory heating, a well-made fully welded ball valve is a long-term investment in leak prevention, lower service costs, and consistent performance.

Get in touch with PANS to discuss certified heating supply valve solutions for your next project.

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Butterfly Valve

- Full Metal-Seated Bi-Directional Butterfly Valve

- High Performance Butterfly Valve

- Three-Eccentric Metal Hard Seal Butterfly Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer