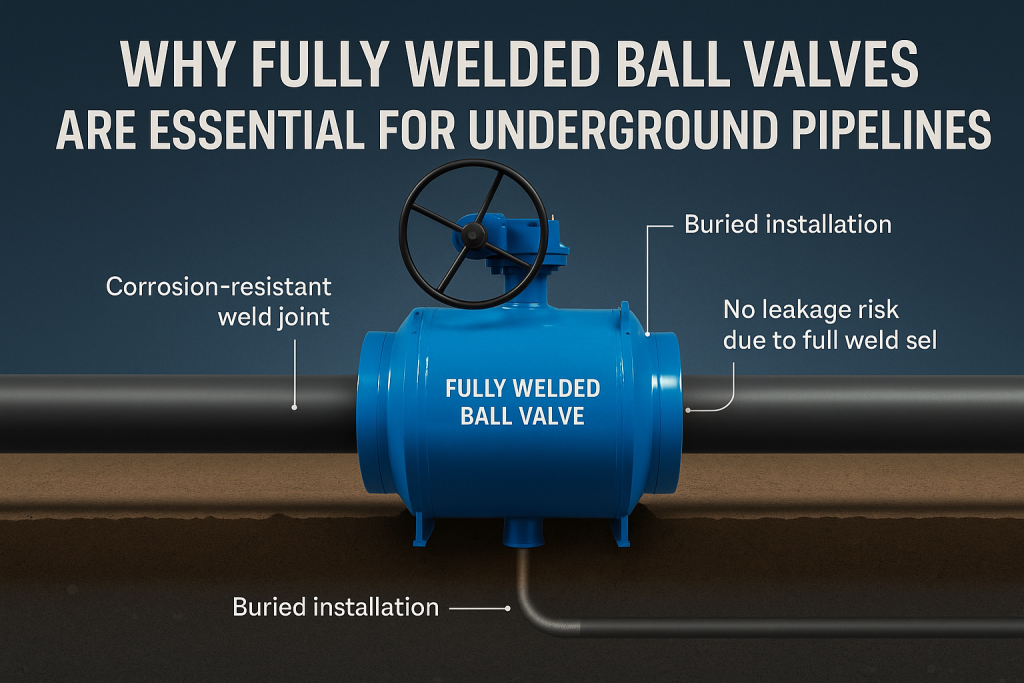

Built to Last: Why Fully Welded Ball Valves are Essential for Underground Pipelines

Fully welded ball valves are essential for underground pipelines because they eliminate leak paths, resist corrosion, and handle ground pressure without failure. Unlike traditional valves, they last longer and require less maintenance once buried. That’s why choosing a reliable underground fully welded ball valve manufacturer matters from day one.

Key Advantages of Fully Welded Designs for Underground Applications

Zero External Leakage Path

The welded body structure eliminates bolted joints, which are the common cause of leaks in traditional valves. With no external fasteners, the valve body becomes a single pressure boundary. This makes it ideal for environments where leakage is unacceptable.

Fully welded valves are commonly used in underground pipelines carrying gas, crude oil, or chemicals. Once buried, the valve does not require routine checks for gasket wear or bolt retightening.

Corrosion Resistance

Underground environments are harsh. Moisture, soil movement, and chemical exposure are constant threats. That’s where coatings and materials come into play.

At PANS Valve, protective coatings follow CE and API standards to ensure long-term performance. Each underground fully welded ball valve is coated with 3LPE, a three-layer polyethylene system that resists soil acidity and prevents moisture ingress. Combined with corrosion-resistant materials like stainless or duplex steel, these coatings protect against damage in aggressive soil conditions.

High Strength & Durability

Buried pipelines experience mechanical stress from soil pressure, vibration, and surface traffic. Fully welded ball valves are built to withstand these forces without cracking or leaking.

Compared to split-body valves, their seamless body construction resists misalignment and fatigue. This durability is one reason industries in Central Asia, the Middle East, and other regions rely on suppliers with consistent manufacturing capacity. PANS, for example, produces over 3,000 tons of valves per year to meet those demands.

Your Expert Underground Fully Welded Ball Valve Manufacturer

As a premier underground fully welded ball valve manufacturer, we deliver certified valves engineered for long-term, maintenance-free performance in critical buried applications. Partner with us for reliable solutions that guarantee operational safety and direct-from-factory value.

View Specifications

Design Features to Look For in an Underground Valve

Stem Extensions

Since underground valves are not easily accessible, stem extensions allow operators to control the valve from the surface. These extensions should match installation depth and allow for safe, convenient operation without excavation.

Actuator Compatibility

In many underground systems, manual operation is impractical. A quality valve should allow seamless integration with electric, pneumatic, or hydraulic actuators. This enables remote control and supports automation through SCADA or pipeline management systems.

Protective Coatings (e.g., 3LPE)

For buried installations, 3LPE remains the standard for corrosion protection. It includes an epoxy primer, adhesive layer, and outer polyethylene shell, shielding the valve from rust, abrasion, and moisture.

Manufacturers must ensure that coating thickness, adhesion, and surface preparation meet international standards. At PANS, we test every underground fully welded ball valve to CE and API specifications before shipment.

Fully Welded vs. Traditional Valves: What Sets Them Apart

For underground use, fully welded vs. traditional valves outperform traditional valve types like bolted or flanged designs in every key area. While traditional valves may have a lower upfront cost, they often introduce long-term risks, especially when buried.

The main differences come down to leakage risk, maintenance frequency, and resistance to environmental stress. Here’s how they compare:

| Feature | Fully Welded Ball Valve | Traditional Bolted Valve |

| Leakage Risk | No external joints, zero leak path | Multiple joints, potential leak points |

| Corrosion Resistance | Sealed body, 3LPE coating standard | Exposed bolts and flanges prone to rust |

| Maintenance Requirements | Minimal; no retightening needed | Regular checks and gasket replacement |

| Durability Underground | Withstands vibration, soil stress | Susceptible to joint fatigue |

| Installation Footprint | Compact, weld-ready body | Requires more space for flanges |

| Lifecycle Cost | Higher upfront, lower over time | Lower upfront, higher maintenance cost |

While both types serve a purpose, fully welded valves are clearly better suited for critical buried systems where safety, uptime, and long-term ROI matter.

Installation and Maintenance Considerations for Buried Valves

Underground valves must be dependable from day one. Once installed, they are difficult to access, which is why build quality and pre-delivery testing matter.

Look for valves that undergo hydrostatic pressure testing, stem torque validation, and leak checks before they leave the factory. A fully welded body also eliminates the need for bolt retightening or gasket replacement later on.

Maintenance is minimal. Periodic checks of actuator function and stem movement are usually all that’s needed. For contractors and municipalities, this leads to lower operating costs and fewer service disruptions over time.

Conclusion

Fully welded valves provide leak protection, structural strength, corrosion resistance, and a low-maintenance design suited for underground systems where access is limited and repairs are expensive.

PANS is trusted as a leading underground fully welded ball valve manufacturer for infrastructure projects across Central Asia, the Middle East, and other regions. We support wholesale underground fully welded ball valve orders with short lead times, strict quality control, and a production capacity of over 3,000 tons annually.

Our record of 0 negative reviews from customers reflects our commitment to long-term performance. Every valve is built for durability, safety, and peace of mind.

Contact us to explore certified underground valve solutions for your project. We’ll help you specify the right product, backed by international standards and real-world reliability.

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Butterfly Valve

- Full Metal-Seated Bi-Directional Butterfly Valve

- High Performance Butterfly Valve

- Three-Eccentric Metal Hard Seal Butterfly Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer