Understanding the Importance of ISO Certifications in Valve Manufacturing

ISO certifications in valve manufacturing are important because they guarantee quality control, ensure safety compliance, and reduce your procurement risks. Valve ISO standards like ISO9001, ISO14001, and ISO45001 mean you get consistent product quality, environmental responsibility, and verified manufacturing processes. For buyers, this translates to fewer defective valves, better supplier reliability, and confidence that valve standards are met every time.

What ISO Certifications Actually Mean

When you see ISO manufacturing on a supplier’s website, it’s not just marketing speak. The International Organization for Standardization creates global standards that companies must follow to get certified.

Think of it like this: anyone can claim they make quality products, but ISO certification means an independent third party has audited their processes and confirmed they actually do what they say.

ISO certification for manufacturing company status requires passing rigorous inspections of quality systems, environmental practices, and safety procedures. It’s proof that the manufacturer follows consistent, documented processes.

Why This Matters When Buying Valves

Valves might look simple, but they’re precision-engineered components that can make or break your operations. When a valve fails in a power plant or chemical facility, you’re looking at safety risks, environmental issues, and expensive downtime.

Quality You Can Count On

ISO-certified manufacturers follow documented procedures for every step of production. This means the valve you get today will be made the same way as the one you get next month. No surprises, no quality variations.

Reduced Risk

Valve standards under ISO certification catch problems before they reach you. Internal audits, process controls, and continuous improvement mean fewer defective products and fewer headaches for your projects.

Regulatory Compliance Made Easy

Many industries require suppliers to hold specific certifications. ISO standards help you meet these requirements without having to verify every detail of your supplier’s operations yourself.

The Three Key ISO Standards for Valve Manufacturing

Not all ISO standards are the same. Here are the three that matter most in valve manufacturing:

| ISO Standard | Focus Area | Key Benefit for Buyers |

|---|---|---|

| ISO 9001 | Quality Management | Consistent product quality and reliability |

| ISO 14001 | Environmental Management | Sustainable practices and compliance |

| ISO 45001 | Worker Safety | Better processes and reliable suppliers |

ISO 9001: Quality Management

Quality management ensures consistent valve performance from design through delivery. ISO 9001 requires systematic processes that eliminate variations and defects, ensuring every valve meets the same standards.

Key requirements:

- Documented quality procedures

- Regular internal audits

- Customer feedback systems

- Continuous improvement processes

- Supplier quality control

What this means for you: Consistent product quality and faster problem resolution when issues arise.

ISO 14001: Environmental Management

Environmental responsibility reduces costs while meeting customer sustainability demands. ISO 14001 requires systematic environmental management that goes beyond basic compliance to improve resource efficiency.

Key requirements:

- Waste reduction programs

- Energy efficiency measures

- Pollution prevention

- Sustainable resource use

- Environmental compliance tracking

What this means for you: Supports your sustainability goals and helps meet environmental reporting requirements.

ISO 45001: Worker Safety

Worker safety directly impacts product quality and manufacturing reliability. ISO 45001 creates systematic safety management where well-trained, protected workers produce higher quality products.

Key requirements:

- Hazard identification systems

- Risk assessment procedures

- Safety training programs

- Incident reporting processes

- Emergency response plans

What this means for you: Better safety practices often correlate with better overall quality and more reliable suppliers.

How ISO Certifications Improve Valve Quality

ISO certifications create systematic approaches to quality that go beyond basic product testing. They establish frameworks for consistent performance across all manufacturing operations.

Process Standardization

Valve standards under ISO certification require documented procedures for every manufacturing step. This eliminates variations that can lead to quality problems and ensures each valve meets the same high standards regardless of when it’s produced.

Supplier Quality Control

ISO-certified manufacturers must evaluate and control their suppliers, ensuring raw materials and components meet quality requirements. This creates quality assurance throughout the entire supply chain.

Continuous Improvement Culture

ISO standards require ongoing monitoring and improvement of processes. This means certified manufacturers continuously work to enhance quality, reduce defects, and improve customer satisfaction.

PANS Valve Is Known for ISO Certification Excellence

PANS Valve holds comprehensive ISO certification for manufacturing company standards that cover quality, environment, and safety. We maintain ISO9001, ISO14001, and ISO45001 certifications, demonstrating our commitment to excellence across all operations.

Our Quality Commitment

Our ISO 9001 certification ensures every valve ISO product meets strict quality requirements. We maintain documented processes, conduct regular audits, and focus on continuous improvement throughout our operations.

Environmental Responsibility

ISO 14001 certification reflects our commitment to environmental protection. We actively manage waste, conserve energy, and minimize our ecological footprint while maintaining efficient production.

Safety Excellence

Worker safety is fundamental to our operations. ISO 45001 certification demonstrates our systematic approach to creating safe working conditions and managing risks throughout our facilities.

Benefits When You Choose ISO-Certified Suppliers

Working with ISO-certified valve manufacturers provides real advantages that impact your project success:

Lower Risk Projects

Third-party verification of quality systems reduces supplier risk. You can rely on certified manufacturers to deliver products that meet specifications consistently.

Better Product Performance

Systematic quality control results in more reliable valves with fewer defects. This means reduced maintenance costs, fewer emergency repairs, and better plant availability.

Improved Documentation

ISO requirements include comprehensive documentation and traceability. This helps with regulatory compliance, warranty claims, and quality investigations.

Stronger Partnerships

ISO-certified manufacturers demonstrate professionalism and commitment to excellence. This creates better, more collaborative relationships between you and your suppliers.

How to Verify ISO Certifications

Not all certification claims are equal. Here’s how to verify that a supplier’s ISO certifications are legitimate:

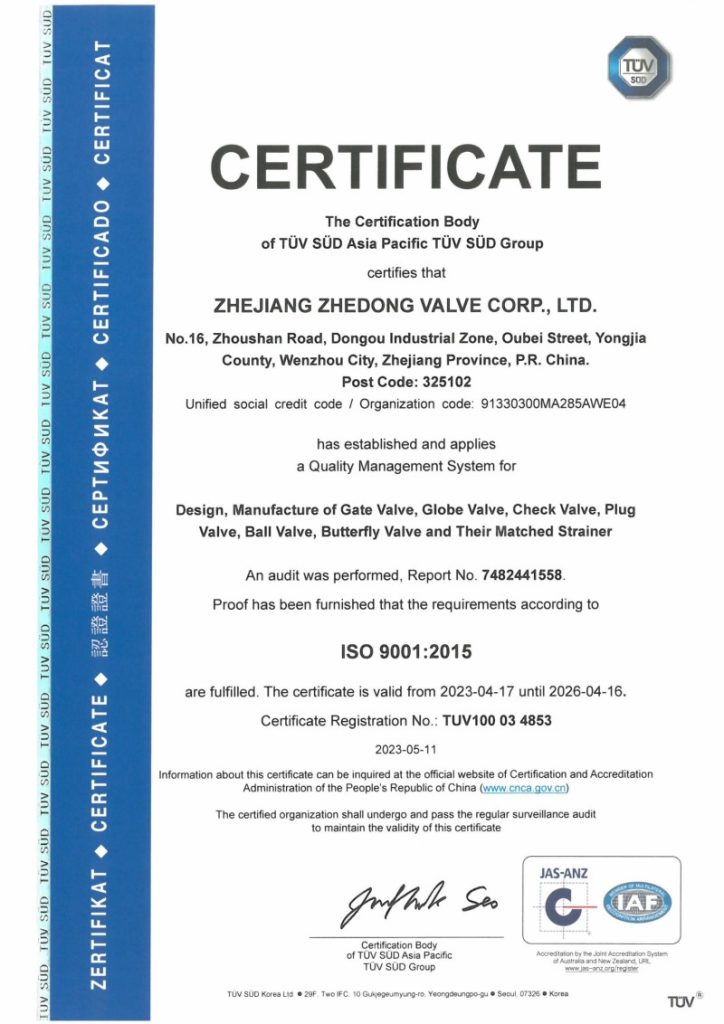

- Check certificate validity. Look for expiration dates, certification body name, and certificate numbers. Valid certificates should be current and issued by accredited bodies like DNV, SGS, or TUV.

- Verify with certification bodies. Contact the certification body directly to confirm active status. Most have customer service lines where you can verify a company’s certification using their certificate number.

- Understand the scope. Certification scope defines exactly what activities are covered. Make sure it includes valve manufacturing, not just general engineering or design services.

- Check public databases. Many certification bodies maintain searchable online registries. You can look up a company’s name to see their current certification status and scope details.

Ongoing Compliance and Monitoring

Valve standards under ISO certification require regular oversight to maintain validity.

Annual Surveillance Audits

Certification bodies conduct yearly audits to verify continued compliance. These check that quality systems remain effective and identify improvement opportunities.

Three-Year Recertification

Complete recertification occurs every three years with comprehensive review of all processes. This ensures certified manufacturers maintain current best practices.

The Future of ISO Standards

Valve ISO standards continue evolving to address new technologies and manufacturing processes. Current trends include digitalization requirements, cybersecurity considerations, and enhanced sustainability metrics.

Leading manufacturers stay ahead of these changes, maintaining certification currency and operational excellence as standards evolve.

Choose The Best, Choose Certified Quality

ISO certifications in valve manufacturing represent proven commitment to quality, safety, and environmental responsibility. For buyers seeking reliable suppliers, ISO-certified manufacturers provide confidence in product quality and delivery performance.

PANS Valve’s comprehensive ISO certification portfolio, detailed on our achievement and contribution page, reflects our dedication to meeting the highest international standards. Our ISO9001, ISO14001, and ISO45001 certifications ensure quality excellence, environmental responsibility, and safety in every valve we manufacture.

Contact PANS Valve today to learn how our ISO-certified manufacturing processes can support your project requirements with reliable, high-quality valve solutions.

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Butterfly Valve

- Full Metal-Seated Bi-Directional Butterfly Valve

- High Performance Butterfly Valve

- Three-Eccentric Metal Hard Seal Butterfly Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Bellow Sealed Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer