All You Need to Know About a Plug Valve

Plug valves are tools used to manage the flow of liquids in pipelines featuring designs like lubricated, eccentric, and sleeved versions tailored to specific purposes.

Their straightforward yet efficient operation involves turning a plug inside the valve body to control the flow.

While plug valves offer benefits such as sealing and lasting durability factors like throttling ability and vulnerability to wear should be considered when choosing the right type for a particular use case.

What is a plug valve?

A plug valve is a valve variety utilized for regulating flow in a pipeline.

It consists of a tapered plug with holes passing through it.

When the valve is open, fluid can pass through these holes in the plug; when it’s closed, the flow is blocked by the plug.

Types of Plug Valves

Lubricated Plug Valves

These valves come with an injection system for lubrication that ensures smooth operation of the plug within the valve body.

This lubrication reduces friction and wear, which prolongs the valve’s lifespan and enhances its performance.

Eccentric Plug Valves

Eccentric plug valves have a design where the plug is positioned off-center in the valve body, creating a cam-like movement when in use.

This setup ensures sealing and less wear on the valve parts making eccentric plug valves ideal for handling pressures or harsh fluids.

Non-Lubricated Plug Valves

When it comes to non-lubricated plug valves, they don’t need external lubrication to function smoothly.

Instead, these valves use self-lubricating materials or coatings on both the plug and valve body to reduce friction and ensure operation.

Sleeved plug valves

Sleeved plug valves come with a sleeve surrounding the plug offering sealing and protection against corrosion and wear.

The sleeve acts as a shield between the plug and the fluid enhancing the valve longevity.

Pressure-balanced Plug Valves

Pressure-balanced plug valves feature a balancing mechanism that lowers the torque needed to operate the valve.

This design is particularly advantageous in high-pressure scenarios as it enhances efficiency and extends equipment lifespan by reducing torque requirements.

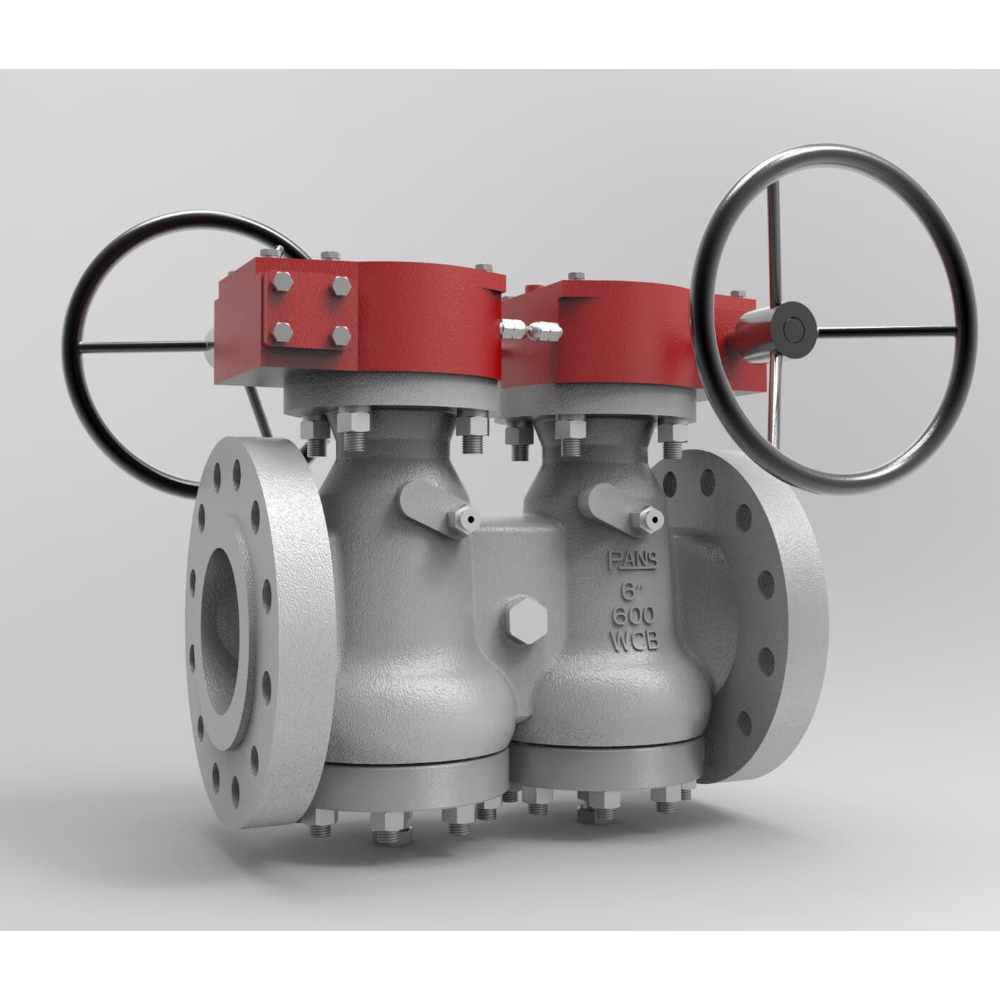

Double Bleed (DBB) Plug Valves

Double bleed (DBB) plug valves are equipped with two seating surfaces for isolation purposes along with a bleed port located between these seats.

This setup allows for both isolating and releasing the fluid in the pipeline at the time improving safety during maintenance or shutdown procedures.

Multiport Plug Valves

These valves have ports and passages in a valve body enabling complex flow arrangements like diversion, mixing, or distribution.

They offer flexibility and save space compared to using single-port valves for the same purpose.

Inverted Plug Valves

In these valves, the plug is positioned upside down from the designs.

This setup can help prevent debris or solids from accumulating on the seating surfaces reducing the chances of valve sticking or leaks in applications with particles in the fluid.

Welded Plug Valves

Constructed with welded joints between components of threaded connections these valves offer increased integrity and leak resistance.

They are suitable for pressure or high-temperature situations due to their welded construction.

Reduced Port Plug Valves

These valves have a plug with a diameter than the valve body leading to flow capacity compared to full port designs.

While they provide resistance to flow and reduce pressure drop these valves may not be ideal, for applications that require high flow rates or minimal fluid obstruction.

How does a plug valve work?

The operation of a plug valve involves the rotation of the plug inside the valve body to manage flow.

When the valve is open, the plug aligns with the flow path enabling fluid to move through the ports.

But when the valve is closed, the plug rotates to block off the flow path effectively stopping the flow.

Plug Valve Working Principle

The core principle behind plug valves is based on rotating the plug to regulate movement within a pipeline.

By adjusting the plug’s position, operators can govern both the flow rate and direction of fluid passing through the valve.

What are plug valves used for?

Isolation: Commonly employed for isolating pipeline sections to aid in maintenance work, repairs, or shutdowns.

Throttling: Used for regulating flow rates within a pipeline by opening or closing the valve.

Diversion: Plug valves enable the redirection of flow between pipelines granting flexibility in processes.

Advantages of Plug Valves

Design: Plug valves boast a design that makes installation and maintenance hassle-free.

Effective sealing: Plug valves offer shutoff reducing the chances of leakage.

Versatility: Plug valves can accommodate an array of fluids, pressures, and temperatures.

Disadvantages of Plug Valves

Limited control precision: When it comes to flow control, plug valves are not as effective as some valve types.

Prone to wear: In pressure or environments, plug valves are susceptible to wear and erosion.

Risk of leakage: Over time, the sealing surfaces of plug valves may deteriorate, potentially leading to leaks.

Plug Valve Components

Plug: The component— conically tapered—that regulates fluid flow through the valve.

Body: The primary structure housing the plug and serving as connection points for pipelines.

Ports: Openings in the plug that permit passage when the valve’s open.

Actuator: The mechanism, for rotating the plug to open or close the valve.

Sealing Surfaces: These are the areas where the plug connects with the valve body to form a seal.

Plug Valve Applications

Oil and Gas: They are utilized in various operations within the oil and gas industry for tasks like isolating, diverting, and regulating fluid flow.

Chemical Processing: In chemical plants, plug valves are essential for managing the flow of dangerous chemicals.

Water Treatment: Water treatment facilities rely on plug valves to control the flow of water and other liquids.

Power Generation: Power plants use plug valves to regulate steam, water, and other fluids in boilers, turbines, and cooling systems.

Plug Valve Flow Direction

The direction of flow through a plug valve is determined by how the ports align with the plug. In a through design, fluid flows linearly through the ports in the plug.

On the other hand, a 90-degree configuration requires fluid to make a right-angle turn as it passes through.

Key Takeaway

Plug valves serve as tools for managing flow in pipelines.

The way a plug valve operates is by turning a plug inside the valve body to control the flow of fluid.

It’s important to grasp the parts, uses, and flow orientation of plug valves for their application in operations.

Search

Categories

Tags

Product

- Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

- Trunnion Ball Valve

- Check Valve

- Cast Lift Check Valve

- Cast Swing Check Valve

- Wafer Type Check Valve

- DIN Valve

- DIN Bellow Sealed Globe Valve

- DIN Globe Valve

- DIN Rising Stem Gate Valve

- DIN Swing Check Valve

- Forge Valve

- Forged Check Valve

- Forged Floating Ball Valve

- Forged Gate Valve

- Forged Globe Valve

- Gate Valve

- Flat Gate Valve

- Wedge Gate Valve

- Globe Valve

- Cast Globe Valve

- Plug Valve

- Eccentricity Plug Valve

- Inverted Pressure Balance Lubricated Plug Valve

- Orbit Plug Valve

- Sleeve Type Plug Valve

- Slurry Valve

- Slurry Valve

- Strainer