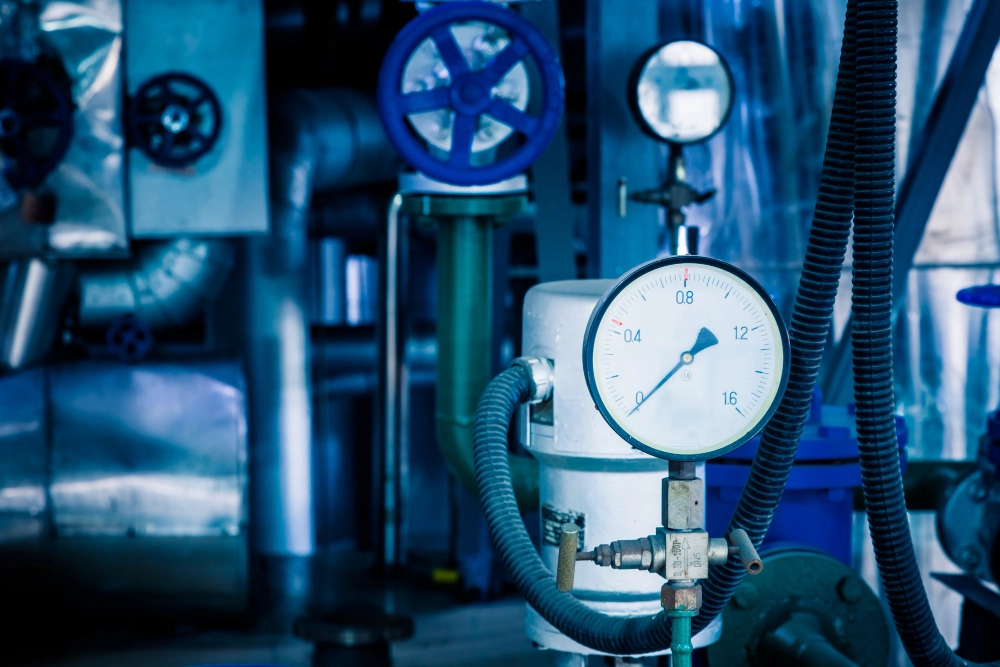

PANS - Power Plant Valves Manufacturer

30+ years expertise, high-temp high-pressure valves for power plants, trusted supply.

Why Choose PANS for Power Plant Valves

Extensive Experience

Over 30 years manufacturing as trusted power plant valves suppliers, specializing in serving EPC contractors and industrial distributors.

High Production Capacity

Annual output exceeds 3,000 tons, most orders delivered within 20 days.

Zero Complaints

As reliable power plant valves suppliers, we provide high-quality components with proven performance.

International Certifications

Where Are Power Plant Valves Used?

Our comprehensive range of valves used in power plant applications is designed to meet the rigorous demands of various energy systems.

For large-scale water circulation, we supply resilient butterfly and check valves. These different types of valves used in power plant cooling systems prevent backflow and regulate flow effectively.

We offer a full line of forged valves for small-bore, high-pressure auxiliary systems, ensuring every part of your operation is equipped with reliable valves in power plant infrastructure. Our expertise also extends to rotor and valve repair for power plants, maintaining system integrity.

Different Types Of Valves Used In Power Plant

Power Plant Ball Valves

What is the ball valve in a power plant? Our diverse range of power plant ball valves meets various pressure and media requirements. From floating ball valves for low-to-medium pressure water and steam lines to trunnion mounted ball valves designed for main steam or cooling water systems, ensuring long life under high pressure. Our fully welded ball valves are ideal for underground piping and long-distance transport of steam or cooling water.

Power Plant Gate Valves

As leading gate valves for power plants suppliers, we offer bellow sealed gate valves for high-temperature, high-pressure applications with zero steam leakage. Our wedge gate valves are suited for main steam and feedwater lines, while flat gate valves are perfect for natural gas, cooling water, and oil pipelines. Our forged gate valves are specifically for small-bore, high-pressure systems.

Globe Valves For Power Plants

Our globe valves are designed for precise flow regulation. The cast globe valve is perfect for boiler feedwater and steam control. For high-pressure, small-bore applications, we offer forged globe valves. Our DIN standard globe valves and bellow sealed globe valves are highly sought after in European markets, offering zero leakage in high-temperature, high-pressure environments. We also specialize in the types of valve used in power plant that require precise control, such as control valves in power plants.

Power Plant Check Valves

We supply a comprehensive range of check valves to prevent media backflow. Our cast swing check valves stop the backflow of steam or water, and cast lift check valves provide protection in high-pressure steam systems. Wafer type check valves are designed for large-bore cooling water systems. We also provide forged check valves for small-bore, high-pressure circuits. These are key valves in nuclear power plants and other critical systems.

Butterfly Valves in Hydro Power Plant

Our specialized butterfly valves are essential for large-bore systems. The three-eccentric metal hard seal butterfly valve is ideal for boiler flue gas and large-bore main steam applications. The full metal-seated bi-directional butterfly valve works reliably in cooling water, circulating water, and flue gas systems. Our high-performance butterfly valves are commonly used as butterfly valve in hydro power plant main inlet valves and cooling systems, and we are a trusted butterfly valve in hydro power plant suppliers.

Get a Quote on Your Power Plant Project

Please fill out the form below or upload your project specifications. Our team will provide a quote within 24 hours.

Power Plant Valves FAQs

How fast is your delivery time?

We understand the importance of project timelines. Most of our power plant valves can be delivered within 20 days to meet your urgent project needs.

Can you provide technical drawings?

Yes, our technical team provides detailed quotes and engineering drawings within 24 hours of your request, ensuring you have the necessary information for your project planning.

What is your minimum order quantity (MOQ)?

We do not have a strict MOQ for industrial products. However, orders ranging from 50 to 100 pieces are an ideal volume for efficient production and delivery.

Do you have overseas customer references?

Yes, we have a long history of successful exports to key markets, including Turkey, the UAE, and Colombia, providing common valves in steam power plants and other sectors. We are an approved supplier for major oil and chemical companies, further demonstrating our reliability.

What valves are used in nuclear power plants?

Nuclear power plants use gate, globe, check, butterfly, and ball valves for high-pressure, high-temperature, and safety-critical systems, ensuring reliable flow control and leak prevention.

Our Partnership

All You Need To Know About Power Plant Valves

At PANS, we ensure power plant valves operate safely and efficiently across thermal, hydro, and nuclear plants. Our expertise covers different types of valves used in power plant systems, lifecycle management, and reliable performance under extreme conditions.

Lifecycle Management of Power Plant Valves

Lifecycle management is becoming essential for power plant valves. Modern utilities demand valves that can be tracked, monitored, and serviced throughout their operating life. With the integration of digital monitoring and traceability systems, operators can reduce unplanned downtime and extend the life of different types of valves used in power plant systems. This includes gate valves for power plants, control valves in power plants, and ball valves used in critical steam cycles. By adopting lifecycle-focused strategies, plant operators ensure reliability, simplify maintenance, and meet safety audit requirements. In today’s industry, lifecycle management is no longer optional — it is a procurement standard.

Green Compliance with Low-Emission Power Plant Valves

Environmental compliance has reshaped the way valves in power plant systems are designed and selected. Valves tested to stringent international standards can achieve fugitive emissions below 100 ppm, supporting both safety and environmental goals. For operators managing critical application valves for thermal power plants, adopting low-leakage solutions reduces environmental risk while ensuring smoother permitting and regulatory approval. Power plant gate valve designs with advanced packing, along with control valve in power plant applications, are increasingly chosen for projects focused on carbon reduction. Low-emission performance is now a driver of long-term credibility and competitiveness.

Valve Applications in Renewable and Nuclear Power Plants

The global shift toward renewable power requires valves in power plant systems that can perform under diverse conditions. In geothermal projects, valves must handle flashing fluids, abrasive particles, and frequent cycling. In hydro power plants, the butterfly valve in hydro power plant design serves as the main inlet valve hydro power plant engineers rely on for large cooling and circulating systems. Nuclear stations depend on valves in nuclear power plants, such as gate and ball valves, to maintain safety in high-pressure and high-temperature environments. In solar thermal plants, the control valve used in thermal power plant boilers regulates heat transfer and steam flow. These examples show how different types of valves in power plant projects are evolving with the energy mix.

Contact Us

Looking for Reliable Power Plant Valves? Partner with PANS – Your One-Stop Industrial Valve Manufacturer.