PANS - Globe Valve Manufacturer

Since 1985, 60,000 m² Factory, 20-day Fast Delivery.

What is a Globe Valve?

A globe valve is a linear motion valve used to start, stop, and regulate fluid flow in a pipeline. PANS has been a professional globe valve manufacturer since 1985. With a total area of 60,000 m² and modern facilities, we are equipped to handle large-scale orders with fast, reliable production. Our products are backed by certifications like API 6D and CE, ensuring quality and performance for global projects.

Size Range:From 1/2 globe valve to 48-inch globe valve (DN15-DN1200). We offer common sizes like 3/4 globe valve, 1 inch, 2 inch, and 4 inch, and can produce large-diameter valves up to 48 inches.

Pressure Rating:Our valves conform to ANSI pressure ratings from Class 150 to Class 2500.

Standards:Our valves are designed and tested to international standards, including API Globe Valve Standard API 6D, ANSI B16.34, BS1873, and CE.

Parts & Internals:Our valves are built with a robust body, bonnet, disc, stem, and packing to ensure durability and leak-free operation.

A globe valve controls fluid flow by moving a disc toward or away from a seat, offering precise throttling and tight shut-off. Typically, flow passes from below the disc upward to enhance control. How a globe valve works is simple: turning the handwheel raises or lowers the stem, which moves the disc to open or close the passage. This straightforward linear motion ensures reliable regulation, making globe valves ideal for applications requiring accurate flow control and dependable sealing.

Globe Valve vs Gate Valve

The main difference between a globe valve vs gate valve lies in their function. While a gate valve is designed for full open or full close operation, a globe valve excels at throttling and regulating flow. This is because the disc and seat design allows for a gradual change in flow area, providing precise control.

Ball Valve vs Globe Valve

When considering a ball vs globe valve, a ball valve provides a quick, quarter-turn on/off function but is not ideal for throttling due to its limited control over flow rate. A globe valve, on the other hand, is specifically engineered for flow regulation, offering better control over pressure and flow.

What is the difference between a globe valve and a plug valve?

A globe valve uses linear motion to control flow, where as a plug valve uses a conical or cylindrical plug that rotates to either block or allow flow. Globe valves are better for throttling, while plug valves are better for quick, tight shut-off.

Can a butterfly valve replace a globe valve?

While butterfly valves are compact and lightweight, they are generally not suitable for fine throttling. For applications requiring precise flow regulation, a globe valve is the preferred choice.

How does a globe valve compare to a check valve?

A globe valve is for active control of flow, while a check valve is a passive device designed to automatically prevent backflow without human intervention.

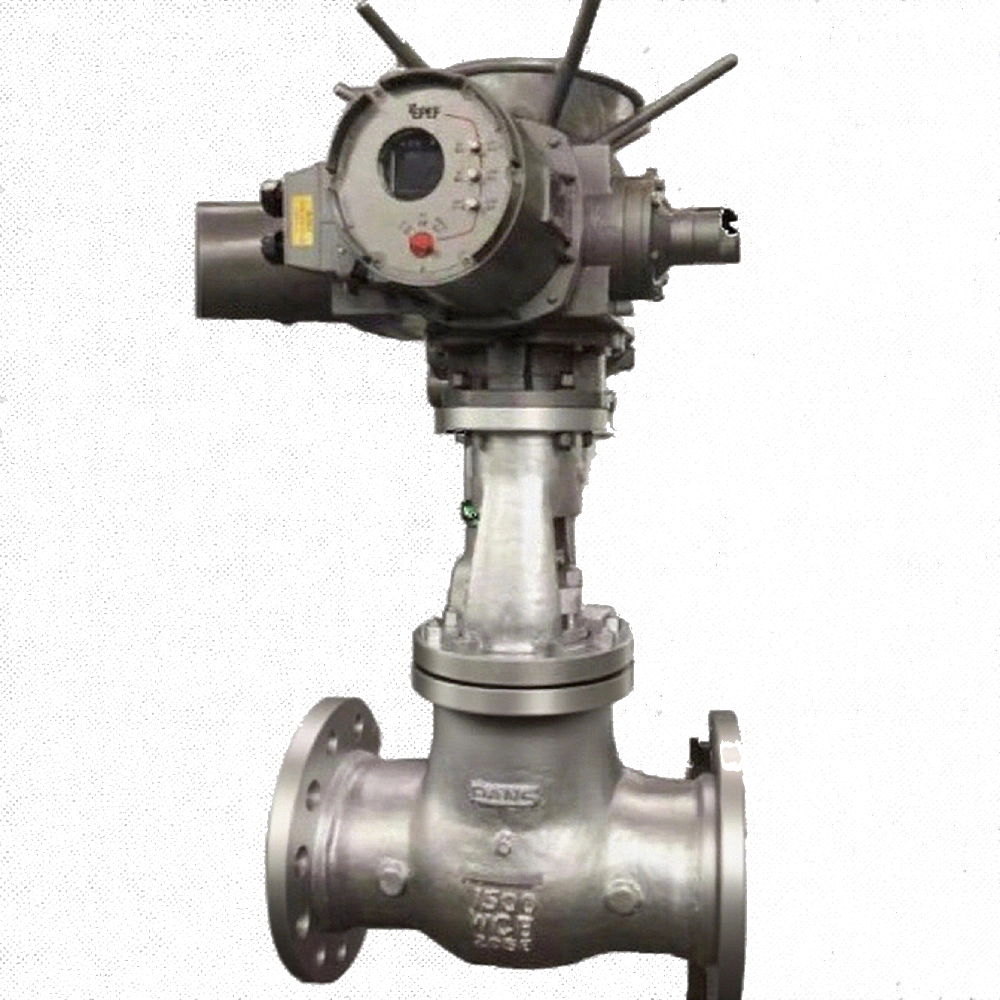

Our Industrial Globe Valve Range

Flange Globe Valve

Standards: BS 1873, ASME B16.34, and API 6D Material: WCB, CF8, and alloy steel Applications: petroleum, chemical, and power industries Models: Class 150 - 600

Pressure Seal Globe Valve

For high-pressure and high-temperature service, PANS offers pressure seal globe valves designed to Class 1500–2500 ratings. The self-sealing pressure seal design ensures zero leakage and enhanced safety, making them the preferred choice in power plants and high-pressure steam systems.

Forged Steel Globe Valve

Manufactured to API 602 standards, our forged steel globe valves are compact, durable, and suitable for high-pressure and high-temperature applications. They are widely used in oil & gas and chemical plants where reliable shutoff is critical.

Cryogenic Globe Valve

Specially designed for low-temperature and cryogenic applications, these valves ensure tight sealing and material stability under extreme cold. Suitable for LNG plants, storage, and transportation systems.

Bellow Sealed Globe Valve

Engineered with bellow seal technology to eliminate stem leakage, these valves are ideal for toxic, flammable, and hazardous media. They provide zero stem leakage and long operational life, often used in chemical and pharmaceutical industries.

All PANS globe valves feature:

- Straight pattern body design with OS&Y, bolted bonnet, rising stem

- Renewable seat rings (threaded, welded, or integral depending on size & material)

- Back seating design for reliable sealing

- Multiple actuation options: handwheel, gearbox, chain wheel, or electric actuator

- Packing seal options: graphite, PTFE, or combined packing with optional Belleville spring loaded system for enhanced reliability

Get a Quote on Your Globe Valve Project

Where is a globe valve used?

PANS globe valves are engineered for precision and reliability across multiple industries. Our valves are commonly used for:

Oil & Gas

For controlling flow in upstream and downstream processing

Power Generation

Our high-pressure and high-temperature valves are essential for steam globe valve and boiler applications.

Chemical & Petrochemical

Handling corrosive fluids and demanding process media

Water Treatment

Used for flow control in municipal and industrial water systems

Why Choose PANS as Your Globe Valve Manufacturer?

Strong Manufacturing

60,000 m² factory, 400+ CNC machines, ensuring precision, large-scale production, and reliable quality.

Certified Quality

ISO 9001, API 6D, CE approvals with strict QC, achieving zero customer complaints.

Fast Delivery

24-hour quote response and 20-day average production lead time

Proven Experience

Trusted by PetroChina, Sinopec, and global projects across the Middle East and Latin America

Contact Our Global Supplier Network

Our Partership

Frequently Asked Questions (FAQ)

What is a globe valve used for?

A globe valve is primarily used for regulating or throttling fluid flow in pipelines. It is not recommended for simple on/off functions

Can a globe valve be installed vertically?

Yes, a globe valve can be installed in any position as long as it is convenient for maintenance and operation.

What is the difference between a globe valve and a gate valve?

The core difference is their function: a gate valve is for complete on/off isolation, while a globe valve is designed for flow regulation. This is a key factor when choosing a valve for a specific application.

What is the price of a globe valve?

The price varies significantly based on material, size (e.g., 1/2 globe valve vs. 12-inch), pressure rating (e.g., globe valve class 800 vs. Class 150), and type (e.g., forged or cast). Please contact us with your specifications for a precise quote.