Your Trusted Butterfly Valve Manufacturer in China

Welcome to PANS Valve, a premier butterfly valve manufacturer in China engineering solutions for the world’s most demanding industries.

Why Partner with PANS for Your Butterfly Valve Needs?

Project-Ready Certifications

Fully certified with API 6D, CE, ISO9001, ISO14001, ensuring our valves meet global project standards and vendor approval lists.

Urgent Delivery, Guaranteed

Your project timeline is our priority. We offer 24-hour quotes and 20-day delivery for most products to meet your tight schedules.

Flexible MOQ for Any Scale

We support both large-scale EPC projects and distributors' stock needs with a No MOQ policy. Order what you need, when you need it.

Decades of Proven Expertise

With a history dating back to 1985 and over 100 patents, our engineering team can tackle any custom requirement you have.

One-Stop Procurement

Simplify your supply chain. Alongside butterfly valves, we manufacture a full line of industrial valves, including Gate, Globe, Ball, and Check valves

Explore Our Advanced Butterfly Valve Portfolio

PANS specializes in high-performance and special-application butterfly valves. We don’t just supply standard products; we provide engineered solutions that solve complex flow control challenges.

Three-Eccentric Metal Hard Seal Butterfly Valve

The pinnacle of butterfly valve technology. The triple-offset geometry eliminates friction between the seal and seat during operation, ensuring bubble-tight, bi-directional shutoff and extending service life dramatically.

Full Metal-Seated Bi-Directional Butterfly Valve

Built to withstand the toughest conditions. The robust metal-to-metal seal provides superior resistance to abrasion, high temperatures, and corrosive slurries where soft-seated valves fail.

High Performance Butterfly Valve

A significant upgrade from conventional concentric valves. The double-offset design reduces seat wear and operating torque, making it a reliable and cost-effective choice for a wide range of industrial applications.

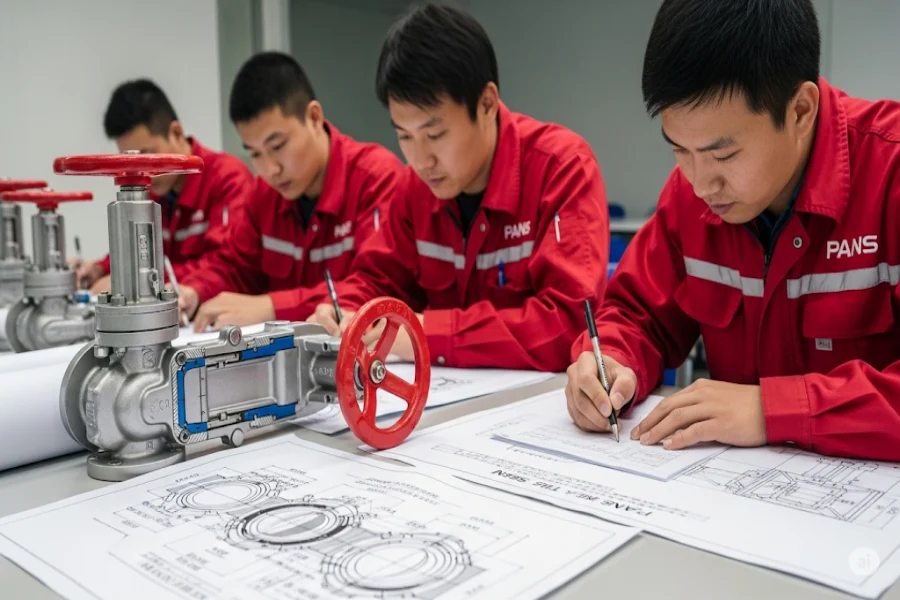

Inside Our Butterfly Valve Manufacturing Process

In our 25,000 m² advanced facility, we don’t just assemble parts—we engineer reliability. Our transparent, five-step process ensures every valve is built for performance and certified to trust.

R&D and Engineering Design

Leveraging 100+ patents, our engineers create custom designs focused on durability and performance. We provide drawings for approval within 24 hours.

Premium Material Sourcing

We select only high-grade raw materials from certified suppliers. Each batch is rigorously inspected to ensure it meets strict quality standards before production.

Precision Machining

Modern CNC equipment machines critical components to exact tolerances. This ensures a perfect seal and flawless performance for every valve.

Controlled Assembly

Our experienced team of over 200 professionals assembles each valve in a controlled environment, ensuring every component is fitted perfectly for reliable operation.

100% Testing & QA

Every single valve is pressure-tested to meet international standards like API and CE. We provide full test reports to guarantee performance and compliance.

Butterfly Valves for Your Industry

Our butterfly valves are trusted by leaders in various sectors. We understand the unique challenges of each industry and provide solutions that enhance safety and efficiency.

We're Here To Answer

All Your Questions

Q1: What is the main difference between a Lug and Wafer type butterfly valve?

The primary difference is in the installation method. A Wafer type valve is clamped between two pipe flanges by long bolts that run from one flange to the other. A Lug type valve has threaded “lugs” or holes on its body that align with the bolt holes on the pipe flanges, allowing it to be bolted directly to one flange. This makes Lug type valves suitable for dead-end service where one side of the piping can be removed for maintenance while the valve remains in place.

Q2: Your valves are certified to API 6D. Do they also meet API 609 standards for butterfly valves?

Yes, our design and manufacturing philosophy is guided by the industry’s most stringent standards. While our API 6D certification primarily covers pipeline valves, our butterfly valves are designed and manufactured in accordance with API 609 standards for dimensions, materials, and testing.

Q3: What is your typical delivery time for a project-scale order (e.g., 100+ pieces)?

Our key advantage is speed and reliability, a major concern for many clients. Thanks to our efficient production system and large capacity (over 3000 tons annually) , we can deliver most standard product orders, including project-scale quantities, within 20 days.For custom orders, we will confirm the delivery schedule when we provide the quote.

Q4: Can I order valves with our company's branding (OEM) or specific material requirements?

Absolutely. We offer full OEM/ODM services. We can customize the valve nameplate with your brand logo and provide valves in specific materials to meet your process requirements(). This is a core service we provide for our distributor and EPC partners.